- Tube Filling Sealing Machine

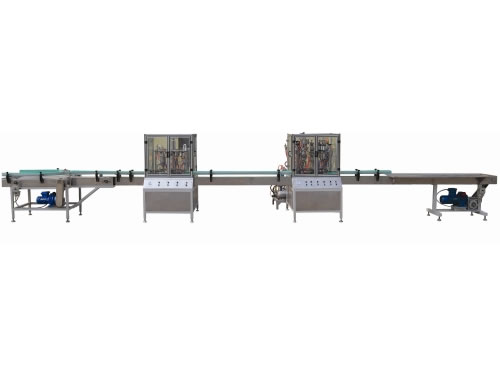

- Monoblock Filling Machine

- ZHNP-50A Nail Polish Filling Plugging Capping Machine

- ZHNP-40 Nail Polish Filling Brushing Capping Machine

- ZHNX-60Y Mechanical Hand Double-Head Eye Drop Filling Capping Machine

- ZHJY-50 Essential Oil Filling Corking and Capping Machine

- ZHS-50 Perfume Filling Capping Pressing Machine

- ZHY-50 Perfume Filling and Capping Machine

- QGQ750 Automatic Aerosol Filling Machine

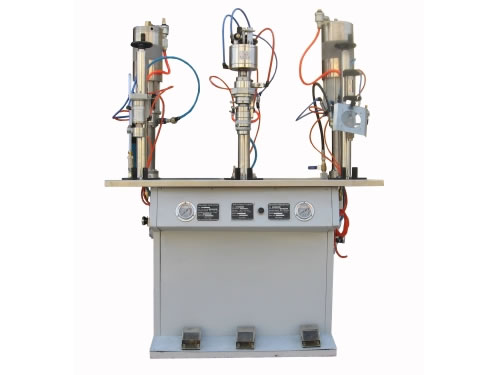

- QGBS-500 3-in-1 Semi-automatic Aerosol Filling Machine

- Bottle Rinsing Filling and Capping Machine

- Recovery Bottles Filling Capping and Labeling Machine

- Filling and Capping Machine

- Eye Drops Filling Machine

- Prefilled Syringe Filling and Stoppering Machine

- Automatic Ampoule Packing Production Line

- Capsule Filling machine

- Aluminum-plastic Automatic Blister Packer

- Pillow Type Packing Machine

- Filling Machine

- Capping Machine

- Labeling Machine

- Shrink Packaging Machine

- Cartoning Machine

- Carton Packing Line

- Other Packing Machine

Monoblock Filling Machine

- ZHNP-50A Nail Polish Filling Plugging Capping MachineThis kind of ZHNP-50A nail polish filling machine is designed to automatically fill, plug, and cap nail polish bottles. Adopting bottle positioning mechanism...

- ZHNP-40 Nail Polish Filling Brushing Capping MachineZHNP-40 nail polish monoblock system includes bottle unscrambling and feeding, filling, brush placement, cap placement and tightening. This nail...

- ZHNX-60Y Mechanical Hand Double-Head Eye Drop Filling Capping MachineZHNX-60Y eye drop filling capping machine is a new machine that we design and make it in these years. This vial filling machine features...

- ZHJY-50 Essential Oil Filling Corking and Capping MachineZHJY-50 essential oil filling machine is designed to automatically fill, cork, and cap essential oil bottles. This liquid bottle capping machine can...

- ZHS-50 Perfume Filling Capping Pressing MachineWe offer precision engineered range of perfume filling machines manufactured in compliance with relevant industry standards. Their filling...

- ZHY-50 Perfume Filling and Capping MachineZHY-50 perfume filling capping machine gathers optics, mechanism, electricity and pneumatics as a unity. This perfume filler and capper features high...

- QGQ750 Automatic Aerosol Filling MachineAdopting advanced technology, QGQ750 automatic aerosol filling machine’s filling end is controlled separately, which will not discharge without filling...

- QGBS-500 3-in-1 Semi-automatic Aerosol Filling MachineThis QGBS-500 3-in-1 aerosol filler is improved, optimized and integrated from original semi-automatic aerosol filling machinery, featuring fast...

- Bottle Rinsing Filling and Capping MachineThis bottle rinsing, filling and capping machine is suitable for various kinds of glass bottles...

- Recovery Bottles Filling Capping and Labeling MachineThe recovery bottles filling, capping and labeling machine is suitable for Chinese liquor, yellow-rice wine...

- Filling and Capping MachineThis filling and capping machine is suitable for high viscosity products such as suspension concentrate...

- Eye Drops Filling MachineThe eye drops filling machine contains several steps as follow: 1.Entering: Place the unfilled bottle on the turn plate by workers and then into the conveyer belt...

Description

Monoblock filler-capper is an integrated filling and capping machine carefully engineered for long-term reliability, versatility and easy changeover. It accurately fills liquids with a wide range of viscosities through the use of either piston pumps or flow meter systems.

Advantages of Monoblock Filling Machine

1. Pressure gravity filling for more viscous products

2. Speeds from 10 to 700 bottles per minute

3. Machine safety and ultra-clean controlled environment enclosures

4. Customized systems to meet your special project requirements

Classification of ZH Monoblock Filling Machine

1. ZHNP-50A Enamel Filling Plugging Capping Machine

2. ZHNP-40 Enamel Filling Brushing Capping Machine

3. ZHNX-60Y Mechanical Hand Double-Head Eye Drop Filling Capping Machine

4. ZHJY-50 Oil Filling Corking and Capping Machine

5. ZHS-50 Perfume Filling Cap Pressing Machine

6. ZHY-50 Perfume Filling and Capping Machine

7. QGQ750 Automatic Aerosol Filling Machine

8. QGBS-500 3-in-1 Semi-automatic Aerosol Filling Machine

Package, Delivery & Payment

Our ZH monoblock filling machines will be packaged by wooden boxes. They are delivered by sea, airplane or by land. Payment by T/T or L/C is acceptable.

Lanteky® Machine. is a professional manufacturer of packing machines in China. We have obtained ISO9001 system and parts of our products have passed CE authentication. If the above mentioned monoblock filling machines (monoblock filler-cappers) interest you, please feel free to contact us.